SWIFT AUXI TECHNIK P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to SWIFT AUXI TECHNIK P.LTD.

Hot Air Dryer

Hot Air Dryer

Designed specifically for regrind 8 dusty material

No perforated cone 8 holes jamming

No material blockage. Material change is quick & easy

On line drying saves power up to 70% as compared to oven

Complete stainless steel construction

User friendly design comprising of viewing window, sliding plate, hinged structure makes operation easier

Dryers are equipped with 7 days timer which helps in programming your production schedule

Hot Air Dryer (Sehd Series)

55501.jpg)

Hot Air Dryer

Designed specifically for regrind 8 dusty material

No perforated cone 8 holes jamming

No material blockage. Material change is quick & easy

On line drying saves power up to 70% as compared to oven

Complete stainless steel construction

User friendly design comprising of viewing window, sliding plate, hinged structure makes operation easier

Dryers are equipped with 7 days timer which helps in programming your production schedule

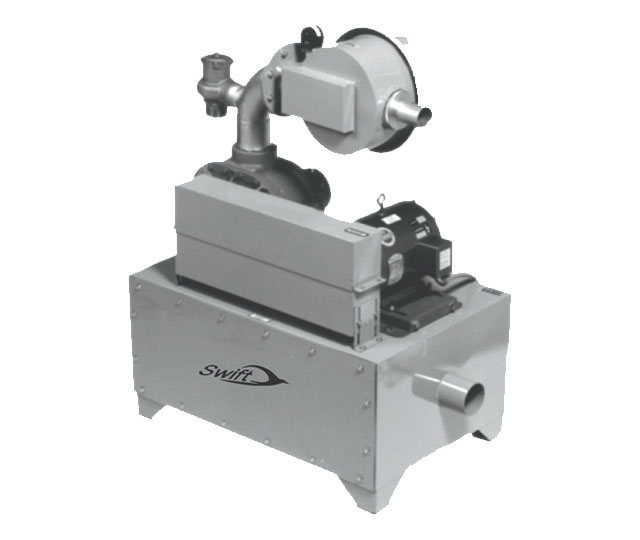

De Humidifier

Unique Features

State-of-the-art twin bed technology

Rock steady dew point at - 40°C. No spikes

Energy saving - much lower cost due to lower regeneration

Linear air flow across the surface area rotor .

Tabular, low resistance wire heaters increase response time

Audible and Visual alarm

Display of return air temperature

Easy and simple maintenance - minimal moving parts

Precise (+/-3degree) adjustable dew point control (Option)

Temperature setback to reduce energy consumption when machine throughput is reduced or stopped

In built Return air after cooler

Uniform mass material flow ensure that each pellet is dried

Even air / heat distribution throughout the dryer

Insulated side wall maintain temperature at desired level

Smooth interior surface

Efficient drying with minimum down time

Quick - clean design in drying hopper

Large hinged doors for easy cleaning

Removable spreader cones makes cleaning fast and easy

Crystallizer

With the increased use of PET in the plastic processing the efficient use of amorphous re-grind material is criticl.

A SWIFT Crystallizing System will allow you convert amophous PET to a Crystalline state that can be bried.THe drying can occur at an elevated temperature to obtain low moisture levels without the feat of agglomeration.

As amorphous PET matrial is loaded into the agitating hopper,the processing temperature is set on the control.when the system is tumed on, the crystallizer automatically direct heated air to the material though the bottom spreader cone of the agitation of the blades prevent agglomeration and material degration during heating.

Reliable High Quality Material Output

Agitating hopper prevents agglomeration

Access doors and removable cone section

PLD control on heat source

Can be easily integated with other material hading equipment.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

55501.jpg)